Bulldog's Semi and Fully Autonomous Deep Lane Shuttle Systems save space and labor!

The Bulldog 2-Way and 4-Way Shuttle Systems are engineered to optimize warehouse space by increasing storage density and reducing forklift needs. The systems can be integrated with AGVs for dock to stock processing!

20+

Years of Experience

Bulldog Semi and Fully Autonomous Shuttles

The Future of Storage has arrived! Increase your storage capacity, reduce redundant forklift usage and improve inventory management.

2-Way Shuttle Systems

Semi-Automatic Shuttle Systems - Enhance Space Utilization

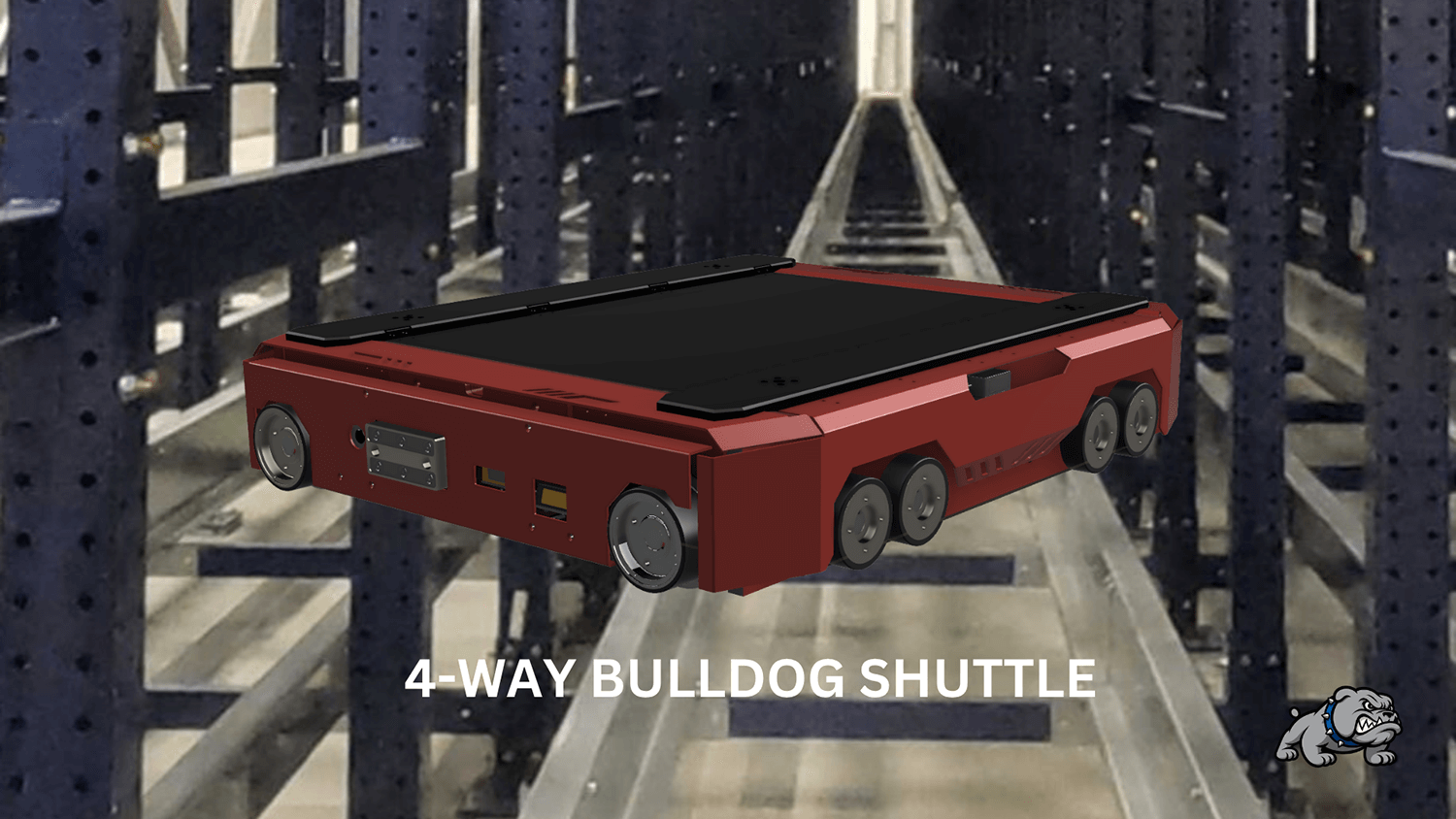

4-Way Shuttle Systems

Fully Autonomous Shuttle Systems - Save Space and Labor

Bulldog Shuttles In-Motion

Induction, Delivery and Retrieval

Measuring, weighing and scanning each pallet at induction is highly important to ensure loads are properly sized and confirmed. Each in-coming pallet ID is scanned for automatic induction and put away. A shuttle is then sent a pick up task. Once the load is picked up by the shuttle, autonomous pathing routes the shuttle for put away.

Autonomous Charging

Bulldog 4-Way Shuttles include automatic battery charging so maintenance personnel do not have to manually change or charge batteries. The Electronic Control System (ECS) monitors state of charge and when a battery reaches a preset discharge level, the system routes the shuttle to a charging station for a 2-3 hour re-charge.

Service Options

-

In-House Service and Parts

-

Self Service and Parts Consignment

-

Forklift Provider and Parts Consignment

Expert Employees

We don’t just work with concrete and We are Approachable, with

- Intermodal Shipping

- Air way Shipping

- Container Freight

Expert Employees

We don’t just work with concrete and We are Approachable, with

- Intermodal Shipping

- Air way Shipping

- Container Freight

Expert Employees

We don’t just work with concrete and We are Approachable, with

- Intermodal Shipping

- Air way Shipping

- Container Freight